We’re Your Best Choice

We combine premium raw materials, strict quality control, flexible color customization, and 20+ years of industry experience to deliver reliable plastic packaging solutions tailored to your needs.

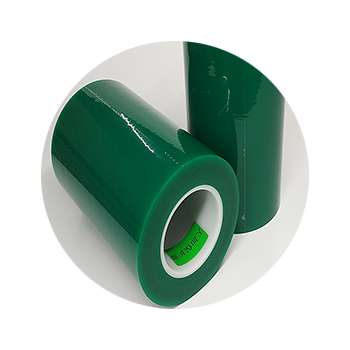

Premium Raw Materials

We use high-quality, eco-friendly PE, PP, and other materials that are FDA, RoHS, ISO9001, and BPA-free certified, making them ideal for food, garment, and document packaging.

Custom Color Options

Choose from a wide range of custom colors including black, white, blue, red, gold, clear, and more. Our vivid, customizable options help elevate your product’s shelf appeal and brand identity.

Strict Quality Control

With over 20 years of manufacturing experience, we implement multi-step inspection processes to ensure secure zippers, smooth sealing, and strong durability in every product.

Professional Team

Our skilled design and engineering team offers fast sampling, responsive service, and flexible OEM/ODM production to bring your custom packaging projects to life efficiently.